The vacuum generator is an efficient small vacuum element that uses a positive-pressure air source to generate negative pressure. This makes it necessary to use both positive and negative pressure in places where compressed air is available or in pneumatic systems. In some places, it is straightforward and convenient to obtain negative pressure. Vacuum generators are widely used in industrial automation in machinery, electronics, packaging, printing, plastics, robotics, and other fields. The following are the three operating principles of vacuum generators.

Venturi principle

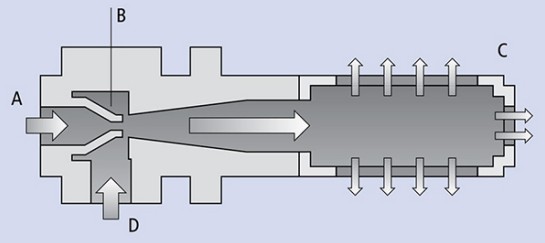

Many vacuum generators are based on the Venturi principle.

Compressed air is fed into the vacuum generator (A), and as the cross-section of the power nozzle (venturi nozzle [B]) decreases, the flow of compressed air increases, and the dynamic pressure increases, while the static pressure decreases.

Once the compressed air passes through the power nozzle, the faster air expands and creates a vacuum. The vacuum port (D) draws the air into the vacuum generator. The compressed air is discharged from the vacuum generator through the silencer (C) and the intake air.

Advantage:

- The vacuum generator working according to the venturi principle is particularly suitable for environments with high acceleration.

- The vacuum clamps can be controlled individually.

- Different types of vacuum generators for centralized and decentralized vacuum generation systems, depending on the specific application.

- Various power levels for different workpieces and applications

- Available for all vacuum systems.

Bernoulli principle

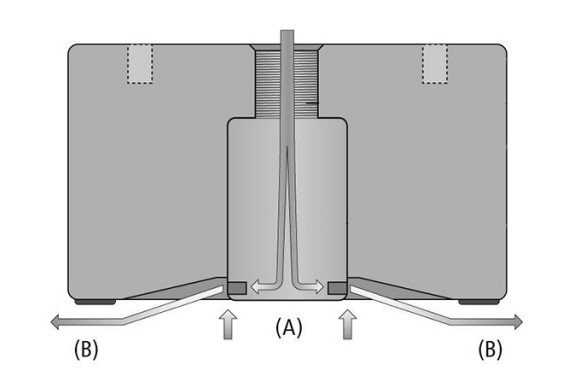

Pneumatic operation using an integrated vacuum generator. Compressed air is discharged through a small hole in the suction cup, and the flow rate increases significantly during the discharge. As the speed increases, the static pressure drops, and a vacuum is created (A) (“Bernoulli’s equation”).

The air with an increased flow rate is expelled from the side (B); an air cushion is formed between the suspended vacuum chuck and the workpiece. The high flow rate compensates for leaks, so even porous workpieces can be handled and separated.

Benefits:

With the Bernoulli effect, workpiece handling can be achieved almost without contact.

Based on Bernoulli’s principle, the vacuum generator allows the safe separation of thin and porous workpieces.

Wall attachment principle

1. Pneumatic operation using an integrated vacuum generator.

2. According to the wall attachment principle, compressed air is introduced through the annular gap, accelerating the flow rate of compressed air.

3. The increase in flow rate produces a wall attachment effect, and the discharged air flows along the protruding surface.

4. The air flowing along the surface creates suction (entrainment) in the surrounding air.

Benefits.

- High adsorption rate and low air consumption under the wall attachment effect (working pressure only 1-5 bar).

- Large contact areas and narrow vacuum ports prevent workpieces from being sucked in or damaged.

- The adsorption area can also be partially fixed.