There is a wide range of rough vacuum generators on the market today for every possible application. Whether you are using oil-sealed or dry vacuum pump technology, optimizing productivity to minimize downtime is essential.

You can maximize the service life of your equipment by performing regular maintenance. In preventive maintenance, you can do many of these items in-house and save yourself from the enormous hassles you may encounter later.

The more time and effort you put into maintaining your vacuum generator, the less you will worry about expensive repairs and replacements. Here are the top five maintenance tips you can put on your list.

Check the surroundings

Your vacuum generator may be mechanically sound but needs the proper environmental conditions to operate at peak efficiency. Check the area around the vacuum generator to ensure it has enough room for unobstructed airflow. Are there any contaminants or solvents in the area that could affect the performance of the vacuum generator? Weather and ambient temperatures can also be an issue, primarily if your vacuum generator operates near an outside wall or heating unit, which can cause condensation and create problems.

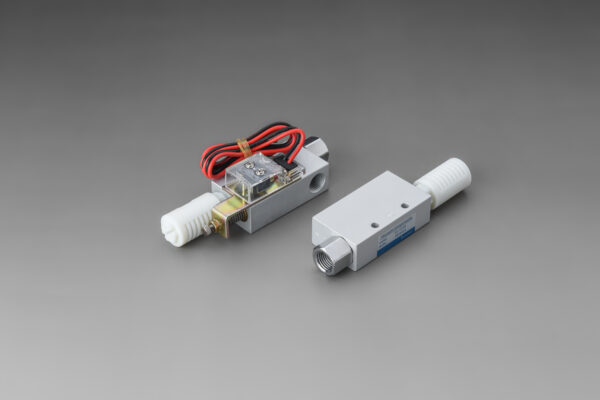

Perform a visual vacuum generator inspection

Most vacuum generators are equipped with field glass, making it easy to inspect the oil inside the vacuum generator frequently visually. Clean oil looks roughly the same color as vegetable oil and gets darker as it collects contaminants. This will help you ensure timely preventive oil changes and avoid costly service. Check for oil or water leaks around the vacuum generator to indicate broader problems. Note any unusual sounds or changes in performance from the unit – both are also indicators of potential service problems.

Change the oil and filter regularly

The maintenance manual with your vacuum generator will provide details of the maintenance intervals required to achieve optimum performance. For dry pumps, gearboxes typically require an annual oil change, while oil-sealed pumps may require monthly oil and filter changes, depending on usage and application. In addition, vacuum generators using radiator air cooling may become clogged with dust from the outside, so periodic debris cleaning is highly recommended to prevent overheating.

Perform a leak test

After installing periodic leak tests on the vacuum generator system, you can ensure that the vacuum is sealed through the various connections. Eliminating these leaks will extend the vacuum generator’s life and improve its operation quality. Preventing foreign matter such as debris, moisture, and oxygen from contaminating your vacuum generator prevents the risk of compromising the integrity of your equipment and reducing its effectiveness.

Create some redundancy in your process

Every vacuum generator requires maintenance and downtime to operate at optimal performance. Ignoring this fact is asking for trouble. You should create some redundancy in your process instead of praying for the best results. Consider having a vacuum generator on hand, vacuum generator efficiency is critical to the successful operation of your business, and downtime can be costly without some backup plan.

These simple maintenance tasks can often be done in-house, while a professional can do others more involved or faster. BOKA will work with you to determine the best vacuum generator solution for your service needs. Contact BOKA for more information.