Model Selection Method

Booka has been focusing on vacuum technology for 30 years,booka vacuum products are

produced using imported raw materials and advanced manufacturing processes

Vacuum suction cup selection method

Selected order of vacuum chucks

(2) The theoretical suction force is obtained from the known sorption area (area of the suction cup x number) and the vacuum pressure. The actual lifting force of the suction cup should take into account the suction method as well as the moving conditions and safety rate.

(3) The mass of the workpiece is compared with the suction force. In order to use the suction force > the workpiece quality, the necessary and sufficient suction cup diameter (suction cup area) is calculated.

(4) Check the shape, material, and buffer of the suction cup from the use environment and the shape and material of the workpiece. The above sequence shows the general vacuum chuck selection sequence, not all of which apply. The final result is tested according to the customer’s requirements and based on this result. The suction cup is determined according to the sorption conditions.

Selected order of vacuum chucks

A.Theoretical suction

●The theoretical suction force is determined by the vacuum pressure and the suction area of the vacuum chuck.

●The theoretical suction force is a value obtained under static conditions. In the occasion of use, it should be given a sufficient amount according to the state of use to ensure safety.

●The vacuum pressure is not as high as possible, and an unexpected situation occurs when the vacuum pressure is high.

●When the vacuum pressure is more than necessary, the wear amount of the suction cup is increased, and cracking is easily caused, so that the life of the suction cup is shortened.

●The vacuum pressure is 2 times, the theoretical suction force is also 2 times, the suction cup diameter is 2 times, and the theoretical suction force is 4 times.

●When the vacuum pressure (set pressure) is set too high, not only will the response time become longer, but the energy necessary to generate vacuum will also increase.

Key points when vacuum chucks are selected

B. About the shear force and torque of the vacuum chuck

●The shearing force of the vacuum chuck (the force of the absorbing surface and the parallel direction) and the moment are not strong.

●Consider the position of the center of gravity of the workpiece to minimize the torque received by the vacuum chuck.

●Not only should the acceleration during movement be as small as possible, but also the wind pressure and impact force should be fully considered. If the acceleration at the time of movement is relaxed, the safety performance of the workpiece falling prevention becomes high.

●The vacuum suction cup should be avoided to raise the vertical direction of the workpiece in the vertical direction (vertical suspension). Please consider the safety rate if it is unavoidable.

●In order not to weaken the torque of the suction cup, do not let the workpiece generate torque during installation. (Refer to Figure ②)

●In the case of horizontal suction work, when moving in the lateral direction, the workpiece is offset by the acceleration and the coefficient of friction between the suction cup and the workpiece. So please control the translation speed. (Refer to Figure ③)

Do not allow the suction area of the suction cup to exceed the surface of the workpiece. If a vacuum leak occurs, the suction is unstable

Where large-area plates are transported using multiple suction cups, the position of the suction cups should be reasonably arranged to enhance the stability of the suction and suspension. Especially for the surrounding area, please confirm the position and carry out piping.

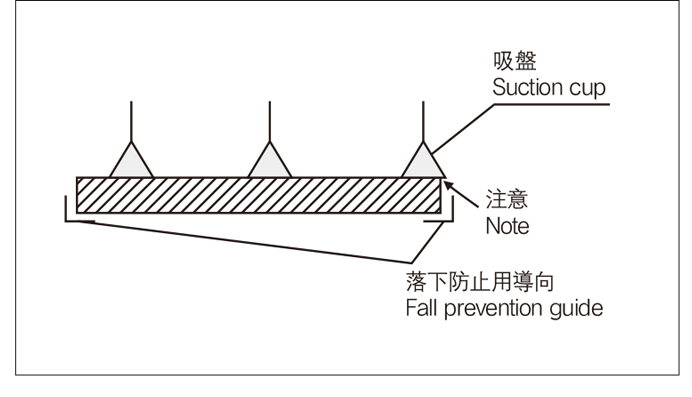

In addition, if necessary, configure an auxiliary tool to prevent the workpiece from falling (example: drop prevention guide)

Installation method

Basically installed horizontally. Try to avoid tilting and vertical mounting. Use a guide to ensure a safe rate if it is a last resort.

● Suction suction and diameter of vacuum chuck

① Seeking theoretical suction

● Set the vacuum pressure below the pressure after the suction is stabilized.

● However, when the workpiece has gas permeability, the surface of the workpiece is rough and it is easy to take in air. This must be considered as the vacuum pressure drops due to inhalation into the atmosphere. Such occasions need to be determined based on the sorption test performed.

● When a vacuum generator is used, the vacuum pressure is about -60 kPa

The suction force of the suction cup can be obtained according to the calculation formula and the theoretical suction force table of Table ①.

According to the calculation formula

● The theoretical suction force can be calculated according to the diameter of the suction cup, the vacuum pressure, and the safety rate.

● The theoretical suction force is divided by the safety rate t, and the suction force can be obtained.

● Suction lifting force = theoretical suction force ÷ t

① Theoretical suction table (Theoretical suction=P×S×0.1)

Vacuum cup shape

● The vacuum chuck has a flat type, a deep type, an organ type, a thin type, a ribbed flat type, an elliptical type, and the like. Please select the most suitable shape according to the workpiece and the environment. In addition, please refer to the company about the shape that is not recorded on the sample.

● According to the shape of the workpiece, the environment of use, and the effects on suitability, sorption traces, and conductivity, it is necessary to determine the material of the vacuum chuck.

● Refer to the examples of handling workpieces in various material categories and confirm the characteristics (suitability) of the rubber before selecting.

Vacuum chuck / handling workpiece example

Buffering presence or absence

● The vacuum chuck has a flat type, a deep type, an organ type, a thin type, a ribbed flat type, an elliptical type, and the like. Please select the most suitable shape according to the workpiece and the environment. In addition, please refer to the company about the shape that is not recorded on the sample.

Where the distance between the suction cup and the workpiece is not constant

In the case where the height of the workpiece is sucked, etc., and the position of the suction cup and the workpiece is uncertain, a built-in spring type buffered suction cup is used. Suction cups and workpieces can be cushioned. In the case where positioning is required again, there is a buffer that cannot be rotated.

Corresponding examples of adapting to workpieces

Note the following for the workpiece shown below

① Where there is a venting hole in the workpiece

② Flat workpiece occasion

③ Soft workpiece

④ About sucker shock

Vacuum chuck durability

● Using a vacuum chuck, the suction surface wears and the shape gradually becomes smaller. As the diameter of the suction cup is reduced, the suction force is also reduced, but sorption is possible.

● The replacement period of the vacuum chuck is greatly affected by the conditions of use, and it is very difficult to estimate the replacement period. Customers should judge based on the use of the situation.