– 1.5 fold round corrugated suction cup for high dynamic handling of high temperature metal sheets up to 250 ℃;

-Handling pre-formed sheet metal parts with a corrugated shape foroptimum adaptability;

-Unloading after forming the part;

– Carrying thin aluminum without deformation and deep drawing;

-Used in automotive industry, such as press line feeding systems.

en planks and other rough surfaces;

-Flat vacuum suction cups: ideal for handling flat, smooth surfaces such as glass, metal sheets, and plastic;

-Vacuum pad gripper: designed for lifting and moving large, heavy objects such as automotive parts, glass sheets, and solar panels.

As a factory owner, you know the importance of finding the right tools to help streamline your operations and increase productivity. That’s where vacuum suction cups and grippers come in. These simple yet powerful devices can help your team handle a wide range of materials quickly and efficiently, making your production process more efficient.

One of the most versatile suction cups today is the 1.5-fold round corrugated suction cup. This specialized suction cup is designed to handle even the most severe operation with short cycle times, making it ideal for busy industrial settings. Whether handling cardboard boxes, wooden boards, or other rough surfaces, this suction cup will help you get the job done quickly and easily.

Consider a specialized grooved suction cup to handle highly rough surfaces such as rough cardboard or oiled metal sheets. These cups are designed to provide extra resistance to lateral forces, ensuring your materials stay in place even during the most challenging operations. And with their unique grooved design, these cups can easily handle even the most difficult materials.

Of course, only some applications require a specialized suction cup. If you’re working with more standard materials like cardboard boxes or wood planks, you may be better off with a standard suction cup. These cups are perfect for handling a wide range of materials quickly and efficiently, and they’re available in various sizes to meet your specific needs.

When handling flat, smooth surfaces like glass, metal sheets, and plastic, there’s no better choice than a balanced vacuum suction cup. These cups are designed to provide maximum suction power while minimizing the risk of damage to your materials, ensuring that your products arrive at their destination in perfect condition.

And if you need to lift and move large, heavy objects like automotive parts, glass sheets, or solar panels, you’ll want to invest in a vacuum pad gripper. These powerful devices are designed to provide maximum suction power and stability, making it easy to move even the heaviest loads quickly and safely.

If you want to know more about different types of vacuum suction cups and grippers, you can contact us now to learn more. Our team of experts can help you find the perfect solution for your unique needs, and we are happy to answer your questions at any time. So why wait? Contact suction cup today and start revolutionizing your industrial operations!

|

Dimensional chart |

||||||||

| Order code | Parameter | |||||||

| ① | ② | ③ | ④ | ⑤ | A | B | C | Model |

| Suction cup bracket type | Suction cup code | Suction cup type | Material | Takeover method | ||||

| VPA | 5 | VB | N

S SE LH XN |

6J 6B B5 |

5 | 12.5 | 6.5 | VPA 5 VB ④⑤ |

| 6 | 7.2 | 16.5 | 30.5 | VPA 6 VB ④⑤ | ||||

| 8 | 9 | 17.5 | 31.5 | VPA 8 VB ④⑤ | ||||

| 10 | 10.5 | 20 | 34 | VPA 10 VB ④⑤ | ||||

| 12 | 12 | 20.5 | 34.5 | VPA 12 VB ④⑤ | ||||

| 15 | 16 | 23.5 | 37.5 | VPA 15 VB ④⑤ | ||||

| 20 | 22.4 | 23.5 | 37.5 | VPA 20 VB ④⑤ | ||||

| 30 | 6J

6B B01 |

33.8 | 34.5 | 63.5 | VPA 30 VB ④⑤ | |||

| 40 | 41 | 38.5 | 67.5 | VPA 40 VB ④⑤ | ||||

| 50 | 52.5 | 41 | 70 | VPA 50 VB ④⑤ | ||||

| 75 | 77.5 | 49 | 78 | VPA 75 VB ④⑤ | ||||

| 110 | – | – | – | – | ||||

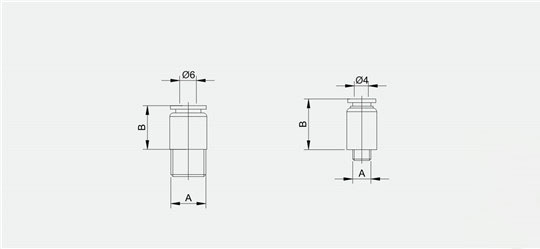

| Dimensional chart Optional quick connector

|

|||

| Quick connection specification | Pipe diameter | A | B |

| POC6-M5C | Ø6 | M5 | 14 |

| POC6-01 | G1/8 | 12 | |

| POC4-M5C | Ø4 | M5 | 14 |

Dimensional chart |

||||||||||||

| Order code | Parameter | |||||||||||

| ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ |

A |

B |

C |

D |

E |

Model |

| Suction cup bracket type | Suction cup code | Buffer stroke | Suction cup type | Material | Swing method | Takeover method | ||||||

|

VPT |

5 | 6 |

VB |

N S SE LH XN |

J K |

6J 6B B5 |

5 | 12.5 | 51.5 | 6 | 15 | VPT 5-6 VB ⑤⑥⑦ |

| 10 | 83.5 | 10 | 43 | VPT 5-10 VB ⑤⑥⑦ | ||||||||

| 15 | 88.5 | 15 | 43 | VPT 5-15 VB ⑤⑥⑦ | ||||||||

| 25 | 98.5 | 25 | 43 | VPT 5-25 VB ⑤⑥⑦ | ||||||||

| 6 | 6 | 7.2 | 16 | 55 | 6 | 15 | VPT 6-6 VB ⑤⑥⑦ | |||||

| 10 | 87 | 10 | 43 | VPT 6-10 VB ⑤⑥⑦ | ||||||||

| 15 | 92 | 15 | 43 | VPT 6-15 VB ⑤⑥⑦ | ||||||||

| 25 | 102 | 25 | 43 | VPT 6-25 VB ⑤⑥⑦ | ||||||||

| 8 | 6 | 9 | 16.5 | 55.5 | 6 | 15 | VPT 8-6 VB ⑤⑥⑦ | |||||

| 10 | 87.5 | 10 | 43 | VPT 8-10 VB ⑤⑥⑦ | ||||||||

| 15 | 92.5 | 15 | 43 | VPT 8-15 VB ⑤⑥⑦ | ||||||||

| 25 | 103 | 25 | 43 | VPT 8-25 VB ⑤⑥⑦ | ||||||||

| 10 | 6 | 10.5 | 20 | 59 | 6 | 15 | VPT 10-6 VB ⑤⑥⑦ | |||||

| 10 | 91 | 10 | 43 | VPT 10-10 VB ⑤⑥⑦ | ||||||||

| 15 | 96 | 15 | 43 | VPT 10-15 VB ⑤⑥⑦ | ||||||||

| 25 | 106 | 25 | 43 | VPT 10-25 VB ⑤⑥⑦ | ||||||||

| 12 | 6 | 12 | 20.5 | 59.5 | 6 | 15 | VPT 12-6 VB ⑤⑥⑦ | |||||

| 10 | 91.5 | 10 | 43 | VPT 12-10 VB ⑤⑥⑦ | ||||||||

| 15 | 96.5 | 15 | 43 | VPT 12-15 VB ⑤⑥⑦ | ||||||||

| 25 | 107 | 25 | 43 | VPT 12-25 VB ⑤⑥⑦ | ||||||||

| 15 | 6 | 16 | 23.5 | 62.5 | 6 | 15 | VPT 15-10 VB ⑤⑥⑦ | |||||

| 10 | 94.5 | 10 | 43 | VPT 15-20 VB ⑤⑥⑦ | ||||||||

| 15 | 99.5 | 15 | 43 | VPT 15-30 VB ⑤⑥⑦ | ||||||||

| 25 | 110 | 25 | 43 | VPT 15-50 VB ⑤⑥⑦ | ||||||||

Dimensional chart Optional quick connector |

|||

| Quick connection specification | Pipe diameter | A | B |

| POC6-M5C | Ø6 | M5 | 14 |

| POC6-01 | G1/8 | 12 | |

| POC4-M5C | Ø4 | M5 | 14 |

Dimensional chart |

||||||||||||

| Order code | Parameter | |||||||||||

| ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | A | B | C | D | E | Model |

| Suction cup bracket type | Suction cup code | Buffer stroke | Suction cup type | Material | Swing method | Takeover method | ||||||

| VPT | 20 | 10 | VB | N

S SE LH XN |

J

K |

6J

6B B5

|

22.4 | 23.5 | 76.5 | 10 | 23 | VPT 20-10 VB ⑤⑥⑦ |

| 20 | 114.5 | 20 | 51 | VPT 20-20 VB ⑤⑥⑦ | ||||||||

| 30 | 124.5 | 30 | 51 | VPT 20-30 VB ⑤⑥⑦ | ||||||||

| 50 | 170.5 | 50 | 77 | VPT 20-50 VB ⑤⑥⑦ | ||||||||

| 30 | 10 | 33.8 | 29.5 | 82.5 | 10 | 23 | VPT 30-10 VB ⑤⑥⑦ | |||||

| 20 | 120.5 | 20 | 51 | VPT 30-20 VB ⑤⑥⑦ | ||||||||

| 30 | 130.5 | 30 | 51 | VPT 30-30 VB ⑤⑥⑦ | ||||||||

| 50 | 176.5 | 50 | 77 | VPT 30-50 VB ⑤⑥⑦ | ||||||||

Dimensional chart Optional quick connector |

|||

| Quick connection specification | Pipe diameter | A | B |

| POC6-M5C | Ø6 | M5 | 14 |

| POC6-01 | G1/8 | 12 | |

| POC4-M5C | Ø4 | M5 | 14 |

Dimensional chart |

||||||||||||

| Order code | Parameter | |||||||||||

| ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | A | B | C | D | E | Model |

| Suction cup bracket type | Suction cup code | Buffer stroke | Suction cup type | Material | Swing method | Takeover method | ||||||

|

VPT |

40 | 10 |

VB |

N

S SE LH XN |

J

K |

6J

6B B01 |

41 | 35.5 | 125 | 11 | 50 | VPT 40-10 VB ⑤⑥⑦ |

| 20 | 135 | 21 | 50 | VPT 40-20 VB ⑤⑥⑦ | ||||||||

| 30 | 145 | 31 | 50 | VPT 40-30 VB ⑤⑥⑦ | ||||||||

| 50 | 190 | 51 | 75 | VPT 40-50 VB ⑤⑥⑦ | ||||||||

| 50 | 10 | 52.5 | 39 | 28.5 | 11 | 50 | VPT 50-10 VB ⑤⑥⑦ | |||||

| 20 | 138.5 | 21 | 50 | VPT 50-20 VB ⑤⑥⑦ | ||||||||

| 30 | 148.5 | 31 | 50 | VPT 50-30 VB ⑤⑥⑦ | ||||||||

| 50 | 193.5 | 51 | 75 | VPT 50-50 VB ⑤⑥⑦ | ||||||||

| 75 | 10 | 77.5 | 49 | 114 | 10 | 35 | VPT 75-10 VB ⑤⑥⑦ | |||||

| 20 | 124 | 20 | 35 | VPT 75-20 VB ⑤⑥⑦ | ||||||||

| 30 | 147 | 30 | 48 | VPT 75-30 VB ⑤⑥⑦ | ||||||||

| 50 | 185 | 50 | 66 | VPT 75-50 VB ⑤⑥⑦ | ||||||||

| 110 | 30 | 115 | 62.5 | 182.5 | 27 | 68 | VPT110-50 VB⑤⑥⑦ | |||||

Dimensional chart Optional quick connector |

|||

| Quick connection specification | Pipe diameter | A | B |

| POC6-M5C | Ø6 | M5 | 14 |

| POC6-01 | G1/8 | 12 | |

| POC4-M5C | Ø4 | M5 | 14 |

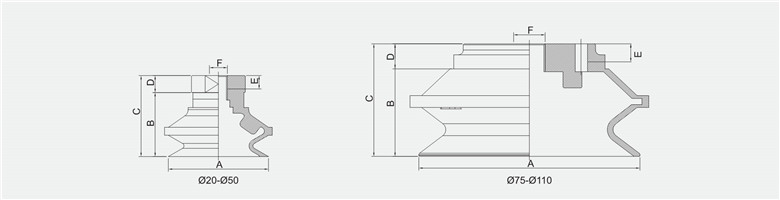

1.5 fold corrugated -Attached type

Dimensional chart (external thread) |

||||||||||

| Order code | Parameter | |||||||||

| ① | ② | ③ | ④ | A | B | C | D | E | F | Model |

| Suction cup bracket type | Suction cup code | Material | Optional connector | |||||||

| VB | 5 | N

S SE LH XN |

M5 | 5 | 9 | 16 | 3.5 | 3.5 | M5×0.8 | VB 5 ③-M5 |

| 6 | 7.2 | 13 | 20.5 | 3 | 4.5 | M5×0.8 | VB 6 ③-M5 | |||

| 8 | 9 | 13.5 | 21 | 3 | 4.5 | M5×0.8 | VB 8 ③-M5 | |||

| 10 | M5

18M |

10.5 | 16 | 24.5 | 4 | 4.5 | M5×0.8 | VB 10 ③-M5 | ||

| 12 | 12 | 16.5 | 25 | 4 | 4.5 | M5×0.8-G1/8 | VB 12 ③-④ | |||

| 15 | 16 | 19.5 | 28 | 4 | 4.5 | M5×0.8-G1/8 | VB 15 ③-④ | |||

| 20 | 22.4 | 19.5 | 28 | 4 | 4.5 | M5×0.8-G1/8 | VB 20 ③-④ | |||

| 30 | 33.8 | 25.5 | 36 | 6 | 4.5 | G1/8 | VB 30 ③-18M | |||

| 40 | 41 | 29.5 | 40 | 6 | 4.5 | G1/8 | VB 40 ③-18M | |||

| 50 | 18M | 52.5 | 33 | 46 | 6 | 7 | G1/8 | VB 50 ③-18M | ||

Dimensional chart (internal thread) |

||||||||||

| Order code | Parameter | |||||||||

| ① | ② | ③ | ④ | A | B | C | D | E | F | Model |

| Suction cup bracket type | Suction cup code | Material | Optional connector | |||||||

| VB | 20 | N

S SE LH XN |

18F | 22.4 | 19.5 | 28.5 | 9 | 8 | G1/8 | VB 20 ③-18F |

| 30 | 33.8 | 25.5 | 34.5 | 9 | 8 | VB 30 ③-18F | ||||

| 40 | 41 | 29.5 | 38.5 | 9 | 8 | VB 40 ③-18F | ||||

| 50 | 52.5 | 33 | 41 | 8 | 8 | VB 50 ③-18F | ||||

| 75 | 18F-38F-12F | 77.5 | 31 | 49 | 18 | 12 | G1/8-G3/8 | VB 75 ③-④ | ||

| 110 | 38F | 115 | 48 | 62.5 | 14.5 | 12 | G3/8 | VB 110 ③-38F | ||

Phone: +86 188 2573 2713

E-mail: marketing@bookavacuum.com

SKYPE: bookaltd@hotmail.com

Adress: BOOKA, Building 2, No. 1, Ma’anshan Street, Liaobu Town,Dongguan City, Guangdong Province

We will contact you within 1 working day, please pay attention to the email with the suffix “marketing@bookavacuum.com”.